Product Description

Pinnacle laminates consist of melamine-impregnated decorative surface papers compressed over phenolic-impregnated kraft paper in press machinery with high pressure and high heat. The finished sheet backs are sanded to maintain thickness uniformity and sheet edges are trimmed to the standard finished sizes.

Recommended Use

Pinnacle decorative laminates are suitable for use on interior residential and commercial furniture, fixtures and casework, and for architectural application on columns, wainscoting, valances cornices, interior doors and divider systems.

General Purpose is most frequently used for work surfaces on counters, islands, vanities, desks and tables. Typical vertical uses include surfacing for wall panels, teller cages and the front panels of workstations, such as those in hospitals, airports and restaurants. Pinnacle laminates are for both horizontal and vertical interior applications where the surface must be functional, durable and decorative.

Standard Sheet Widths

48”

1,219mm

Standard Sheet Lengths

96”

2,438mm

Thickness and Weight

Thickness 0.9mm

Weight per ft² 0.22 lbs

Basic Limitations

Pinnacle laminates are for interior use only. The following substrates are not recommended for direct application: drywall (gypsum board), concrete or plaster. Pinnacle laminates should not be used in areas of extreme temperatures exceeding 275°F (135°C) or extreme humidity areas.

Storing

Pinnacle laminates should be stored horizontally with a protective sheet or board on top to protect from damage. Ideal storage conditions are approximately 75°F (24°C) at 45% to 55% relative humidity. Laminates should be protected from moisture and never stored in contact with the floor or outside wall.

Preconditioning

Ensure the face laminate, backing laminate and the substrate are allowed an appropriate acclimation in the same ambient conditions for a minimum of 48 hours prior to fabrication. Ideal conditions are about 75°F (24°C) at 45% to 55% relative humidity.

Substrates

Pinnacle laminates must be bonded to a suitable substrate, such as particleboard, medium density fiberboard or A-faced plywood. Do not bond directly to high-pressure laminate, drywall (gypsum board), concrete or plaster. Substrates should be sanded smooth, uniform thickness and clean of dust, oil or grease.

Adhesives

Permanent adhesives, such as rigid (urea), semi-rigid (polyvinyl acetate [PVA]), and contact types are recommended. Follow the

instructions recommended by the adhesive manufacturer.

Assembly Recommendations

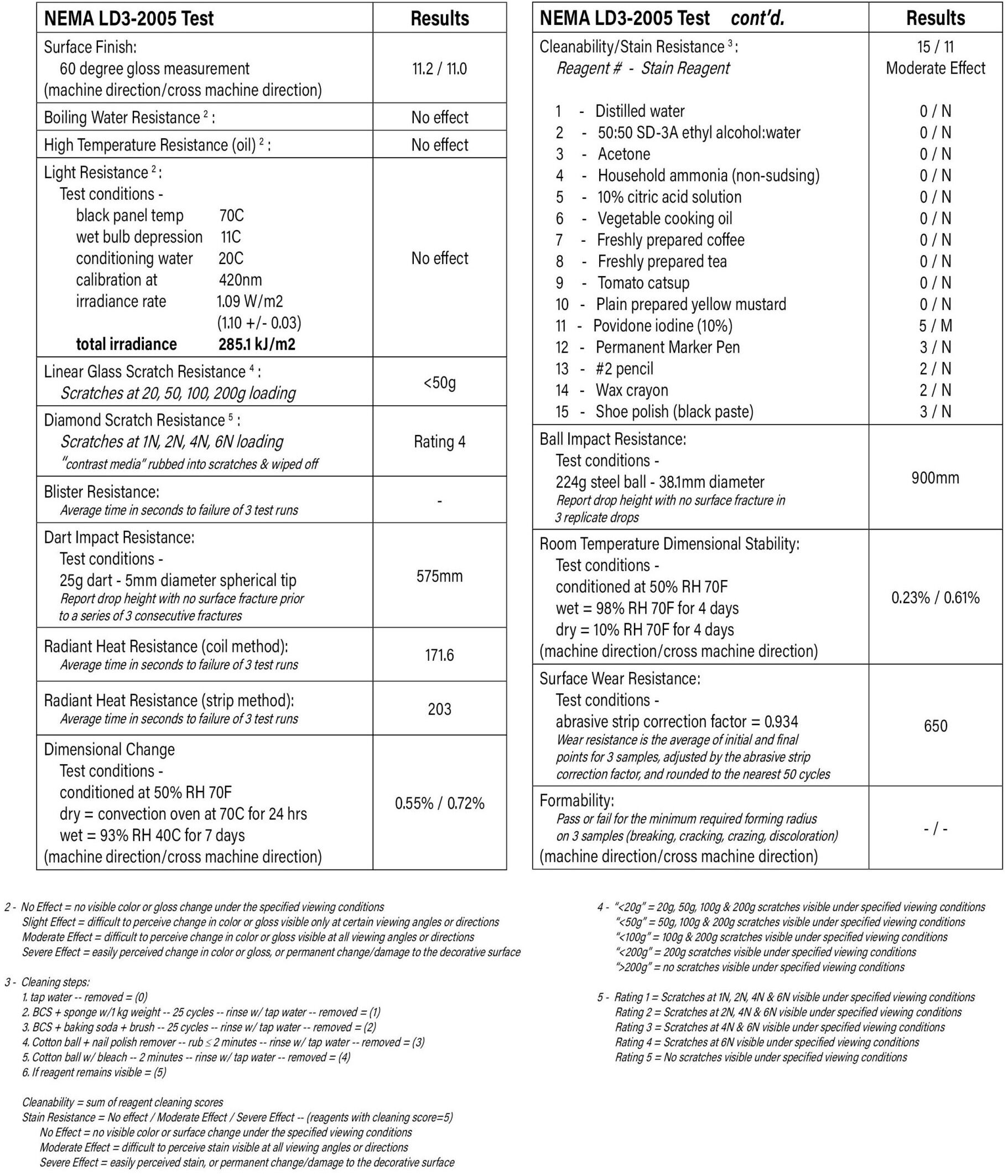

Fabrication should follow the Pinnacle recommended procedures, conditions and practices as specified by ANSI A-161.2-1998 (revised), NEMA LD3-2005 and “Architectural Woodwork Quality Standards, Guide Specifications and Quality Certification Program” guidelines of the Architectural Woodwork Institute where applicable.

To avoid stress cracking, do not use square-cut inside corners. Inside corners must be radiused 1/8” (3.18mm) minimum. All edges and corners should be routed, sanded or filed smooth.

Screw or bolt holes should be drilled oversized. It’s recommended screws or bolts be countersunk into the face side of a laminate-clad substrate.

Pinnacle laminates should be cut, drilled, routed and fabricated using carbide-tipped tools. A high tool speed, low feed speed and use of a hold-down to prevent vibration are strongly encouraged.

Manufacturer

Pinnacle Decorative Laminates brand laminate sheets are manufactured by Crown Decor Pvt. Ltd.

Performance Compliance

Certifications